S4 Ep199: Warehouse Safety Tips | Episode 199 | The 5S Methodology

- Author

- Wes Wyatt

- Published

- Wed 04 Oct 2023

- Episode Link

- https://audioboom.com/channels/5013934-safety-stripes-by-mighty-line-floor-tape-the-best-workplace-safety-podcast-talking-nfpa-ehs

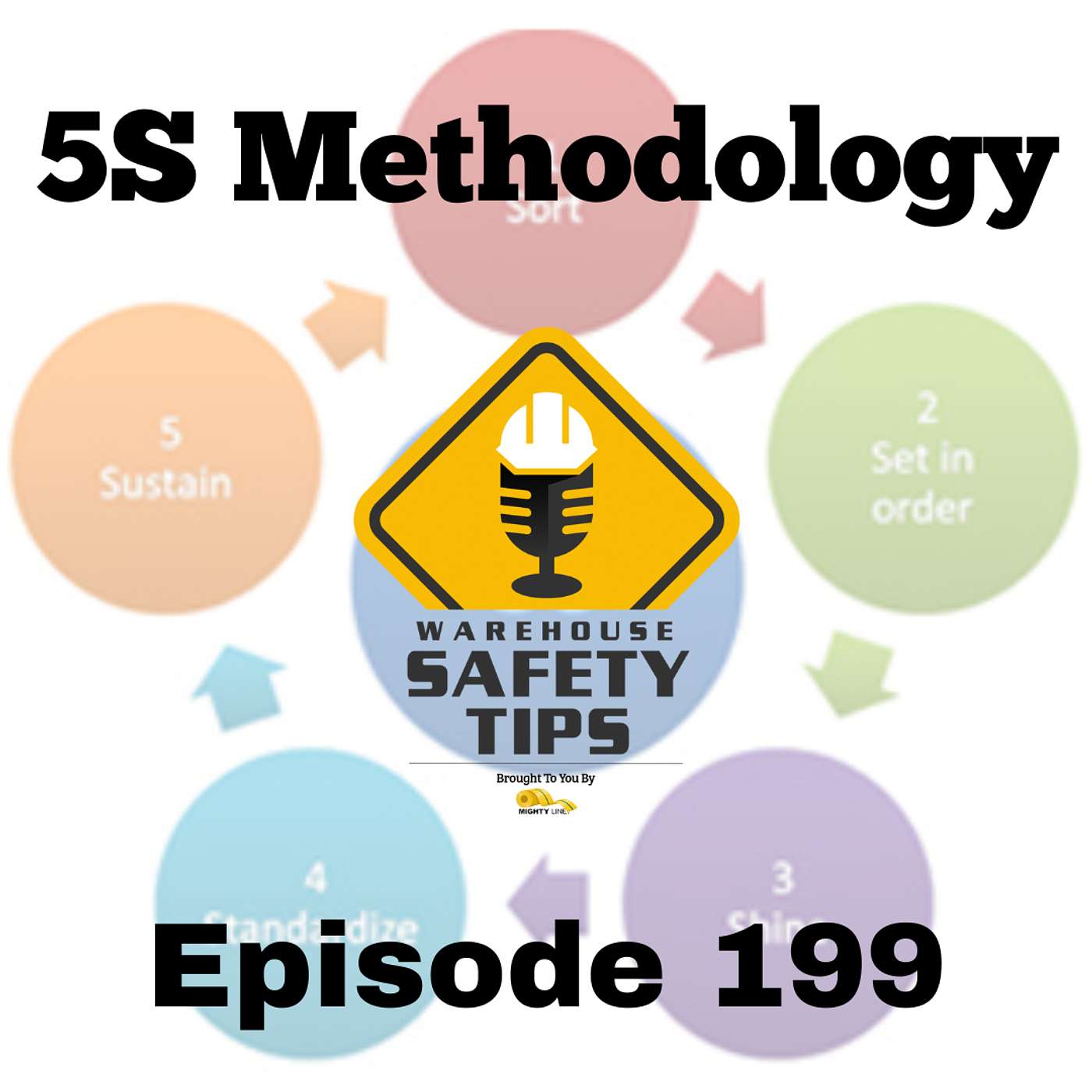

The 5S Methodology

On today's podcast, we'll be talking about The 5S Methodology.

So - stay tuned.

You can find the show notes to each episode, links to the information mentioned on the podcast, the social media platforms we're on, and anything else related to the podcast at WarehouseSafetyTips.com.

If you're a seasoned Podcast Listener, this podcast will be different from most you listen to. It's based on exactly what the name implies - Warehouse Safety Tips. And since the people in that industry are busy - we know time is money so each episode will be as short and to the point as possible.

And now that all that is out of the way - let's get to the Podcast!

The 5S Methodology

Man alive, does time fly or what?!?

What "feels" like a short time ago - we started bringing you tips and info related to Warehouse Safety. That's the same format we share today - only we've branched out over time to try and include ALL facilities, but keeping our focus on factories and warehouses.

That short time ago has turned into almost FOUR years - every week without fail. We say almost because we're only ten episodes from the four-year mark. And we have YOU to thank for watching and listening each week!

Because The 5S Methodology is vital to overall safety - we've decided to make our next ten episodes centered around it and its components.

So today, we'll start with a basic overview of The 5S Methodology.

Among the many tools and methodologies available to ensure a safe and efficient environment, the 5S Methodology stands out as comprehensive and practical. Let's break down each of its five core components:

Sort (Seiri):

On today's podcast, we'll be talking about The 5S Methodology.

So - stay tuned.

You can find the show notes to each episode, links to the information mentioned on the podcast, the social media platforms we're on, and anything else related to the podcast at WarehouseSafetyTips.com.

If you're a seasoned Podcast Listener, this podcast will be different from most you listen to. It's based on exactly what the name implies - Warehouse Safety Tips. And since the people in that industry are busy - we know time is money so each episode will be as short and to the point as possible.

And now that all that is out of the way - let's get to the Podcast!

The 5S Methodology

Man alive, does time fly or what?!?

What "feels" like a short time ago - we started bringing you tips and info related to Warehouse Safety. That's the same format we share today - only we've branched out over time to try and include ALL facilities, but keeping our focus on factories and warehouses.

That short time ago has turned into almost FOUR years - every week without fail. We say almost because we're only ten episodes from the four-year mark. And we have YOU to thank for watching and listening each week!

Because The 5S Methodology is vital to overall safety - we've decided to make our next ten episodes centered around it and its components.

So today, we'll start with a basic overview of The 5S Methodology.

Among the many tools and methodologies available to ensure a safe and efficient environment, the 5S Methodology stands out as comprehensive and practical. Let's break down each of its five core components:

Sort (Seiri):

- Purpose: Eliminate unnecessary items and declutter the workspace.

- Action: Determine the necessity of each item in the workspace. Remove items that are not essential or are out of place, ensuring everything has its proper place.

Set in Order (Seiton):

- Purpose: Organize items to enhance workflow and efficiency.

- Action: After sorting, arrange items to promote easy access and logical flow. Please consider the frequency of use and ensure that regularly used items are within easy reach.

Shine (Seiso):

- Purpose: Clean the workspace and maintain it in a pristine state.

- Action: Regularly clean every area, equipment, and tool. Keeping everything clean and maintained improves aesthetics and helps detect potential issues like leaks, wear, and tear.

Standardize (Seiketsu):

- Purpose: Implement consistent practices across the board.

- Action: Develop standardized procedures and routines for all tasks. By implementing consistent practices, everyone knows the best and safest way to perform their duties, reducing variability and mistakes.

Sustain (Shitsuke):

- Purpose: Maintain and improve the established procedures.

- Action: Regularly review and audit the processes. Encourage a culture of continuous and never-ending improvement, ensuring that the benefits of the 5S Methodology are retained and built upon over time.

The 5S Methodology provides a systematic approach to creating a safe, efficient, and productive warehouse environment. By understanding and implementing these components, warehouses can significantly elevate their operational standards.

Thank you for being part of another episode of Warehouse Safety Tips.

Until we meet next time - have a great week, and STAY SAFE!<

Thank you for being part of another episode of Warehouse Safety Tips.

Until we meet next time - have a great week, and STAY SAFE!<